Yeast Propagation System

Use the biological engineering concept of pure breed asepsis cultivating, no dead space of tank bodydesign, high finish and easy to clean, a very reliable sterilizing performance, and can through the CIPcleaning to ensure the cleaning and sterilization effect of the entire system.

General information of equipment:

★ Use the biological engineering concept of pure breed asepsis cultivating, no dead space of tank bodydesign, high finish and easy to clean, a very reliable sterilizing performance, and can through the CIPcleaning to ensure the cleaning and sterilization effect of the entire system.

★ Reasonable control procedure, from the CIP cleaning to the whole process sterilization,cooling andcultivateing of wort, inside of tank keeps asepsis air positive voltage 0.5bar, to ensure pure breedculvating of the wort.

★ The smooth design of pipeline, the pipelines all use the closed path design of close type, to ensurethat no dead space when cleaning. The whole system no design of steam leaking, keep the workingplace and environment high health standards.

Equipment characteristics:

★ Accurate manufacturing process: roughness of the tank inside surface is 0.4μm, roughness of the

tank outside surface is 0.8μm.

★ The structure of heating, cooling is unique, highly efficient of heat exchange.

★ Cooling form: shell Miller board interlayer alcohol water for indirect cooling.

★ Heat form: cone bottom Miller board interlayer steam for indirect heating.

★ Welding of the system pipelines use the argon welder, gas shielded, to ensure the inner surfacesmooth of pipeline welding, meet the production requirements of pure breed cultivating, and meet thesafety of CIP cleaning.

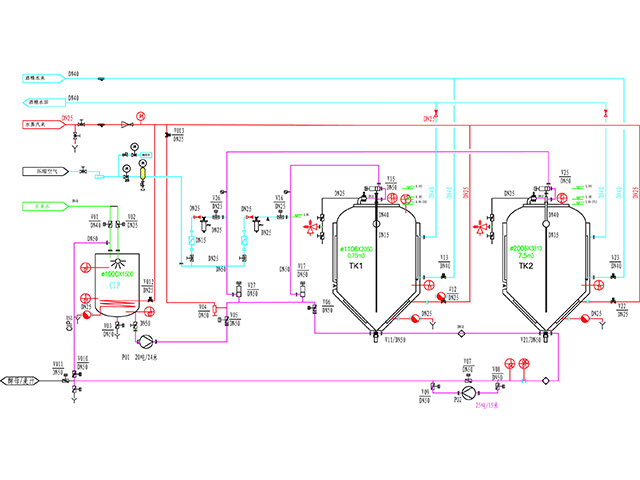

Process flow:

★ The pure wort after levels cultivated in the laboratory, finally go to the Carlsberg flask.

★ Before the expand propagation, do the CIP clean and steam sterilizing for the system containersand the corresponding pipelines.

★ Hot wort (cold wort) by the amount to pick into the seeding tank, a second sterilization for the wortin the tank, and then cooled to the inoculation temperature, and then inoculate the Carlsberg flaskyeast which have been cultivated in the laboratory into, after 36 -- 48 hours of interval ventilationcultivating, then can transfer into the expand cultivating tank.

★ Hot wort (cold wort) by the amount to pick into the cultivating tank, a second sterilization for thewort in the tank, and then cooled to the inoculation temperature, and then inoculate the seedyeast into, after 36-48 hours of interval ventilation cultivating, then can transfer into the expandcultivating tank.

★ When the yeast in the expanded cultivating tank meet the technical requirement, then can hydraulicpressure parts of yeast to the seeding tank, as the seed for low temperature storage, others canpressed into the third class cultivating tank continue cultivating or pressed into the ferment tank forthe wort inoculation of the production site.

System constitute:

★ A variety of models, can meet the various needs of users. There are manual control system,semi-automatic control system and fully automatic system control. Also can designedaccording to the requirements of users.

System self-control:

★ Use of 10.4 inches touch-screen Siemens as a system to monitor the operation and interface,controlled all the parameters and set the whole system can monitor the status of the touch screenon the smooth realization. Yeast culture can foster the temperature, pressure, oxygen conditionsand the amount of wort can be added to achieve automatic control.

★ According to the technological requirements can be cultured yeast for temperature, pressure,oxygen conditions, as well as wort, and other parameters in addition to re-set.

★ May at any time in accordance with the requirements of the operator from the state-controlledswitch to manual operation, may also be manually switch to the state-controlled state.

Two Tanks Method:

★ Two-level cultivating, the expansion timeis 10, the effective volume of the twolevelcultivating tank are as follows:

★ 0.3m3-3.0m3

★ 0.45m3-4.5m3

★ 0.8m3-8m3

Three tanks method:

★ Three-level cultivating, the expansion time is 5, the effective volume of the three-levelcultivating tank are as follows:

★ 0.3m3-1.5m3-7.5m3

★ 0.5m3-2.5m3-12.5m3

★ 0.8m3-4m3-16m3

★ The cultivating tankofⅠlevel and Ⅱ level d can be heated and cooled

★ Configuration: tank-top components with asepsis sanitation type, air-operated doublebeat valve of Definox-defontaine、pressure transmitter of E+H company、bevel seatvalve of German BaoDe company、asepsis sampling Valve of Alfa Laval company,asepsis sanitation type pressure gauge and the temperature pickup、oxygenize pipe andoxygen tubes and central washing ball.

Online enquiry

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

Related products

Yeast Recycle & Storage System

In beer production scene, the yeast can be collected after ferment, sugar descending finished and diacetylene passed, and at the meanwhile, the collected yeast can be stored effectively in a short time;

Learn MoreAuto Yeast Pitching System & Wort Aeration System

This system can continuous add the beer yeast quota to the pipeline of wort, through the mixer can even mix the yeast and wort to maximize, through the special designed oxygenize nozzle, realize quickly dissolve of the gas in the wort.

Learn MoreFermentation CIP System

The perfect Pure Draft Beer CIP design divided into 4 parts: cooling before filterCIP, heating before filter CIP, cooling after filtration.

Learn MoreYeast Propagation System

Use the biological engineering concept of pure breed asepsis cultivating, no dead space of tank bodydesign, high finish and easy to clean, a very reliable sterilizing performance, and can through the CIPcleaning to ensure the cleaning and sterilization effect of the entire system.

Learn More