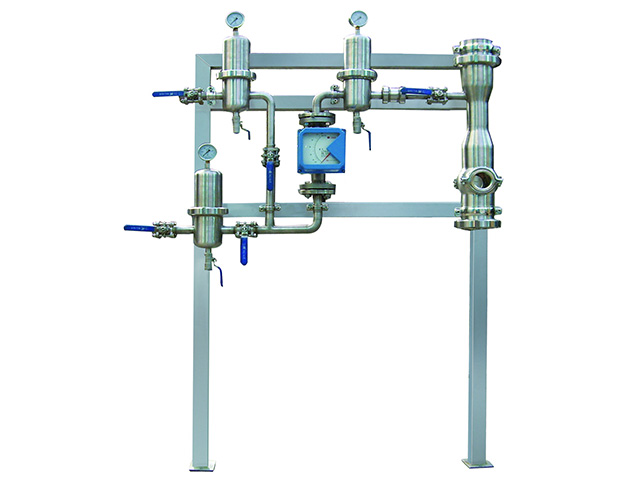

Auto Yeast Pitching System & Wort Aeration System

This system can continuous add the beer yeast quota to the pipeline of wort, through the mixer can even mix the yeast and wort to maximize, through the special designed oxygenize nozzle, realize quickly dissolve of the gas in the wort.

General information of product:

★ This system can continuous add the beer yeast quota to the pipeline of wort, through the mixer can even mix the yeast and wort to maximize, through the special designed oxygenize nozzle, realize quickly dissolve of the gas in the wort. Flowing through the system, through the wort flow counts the collection signal, pass to the PLC control system, set up the frequency of frequency conversion yeast additive pump in the Siemens touch screen, can use the quota adding or proportion adding, also the electrical flowmeter record the immediate flow and accumulated flow.

Equipment characteristics:

★ The design and manufacture level of this equipment with the international level, all the components use the international well-known products. Can through setting up wort adding flow to control the frequency conversion cam . rotor pump , also can through the wort flow to control the wort adding flow.

★ Set the CIP bypass pipeline of the adding pump, can ensure the thorough cleaning of the adding pipeline.

★ All parts contact with the materials are sanitation type, all pipelines can carry out steam sterilization, all material pipelines can carry out CIP cleaning.

★ The compressed air after two levels aseptic filtration, air pipes can carry the steam sterilization.

★ The oxygenize nozzle which is special designed can achieve the aim of quickly dissolve when the gas formed turbulent current in the liquid,achieve the needed dissolve oxygen amount of yeast multiplication.

★ Can equip the determinator connector of dissolved oxygen and asepsis sampling valve.

Online enquiry

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

Related products

Auto Yeast Pitching System & Wort Aeration System

This system can continuous add the beer yeast quota to the pipeline of wort, through the mixer can even mix the yeast and wort to maximize, through the special designed oxygenize nozzle, realize quickly dissolve of the gas in the wort.

Learn MoreFermentation CIP System

The perfect Pure Draft Beer CIP design divided into 4 parts: cooling before filterCIP, heating before filter CIP, cooling after filtration.

Learn MoreYeast Recycle & Storage System

In beer production scene, the yeast can be collected after ferment, sugar descending finished and diacetylene passed, and at the meanwhile, the collected yeast can be stored effectively in a short time;

Learn MoreYeast Propagation System

Use the biological engineering concept of pure breed asepsis cultivating, no dead space of tank bodydesign, high finish and easy to clean, a very reliable sterilizing performance, and can through the CIPcleaning to ensure the cleaning and sterilization effect of the entire system.

Learn More