Low temperature sludge dewatering machine

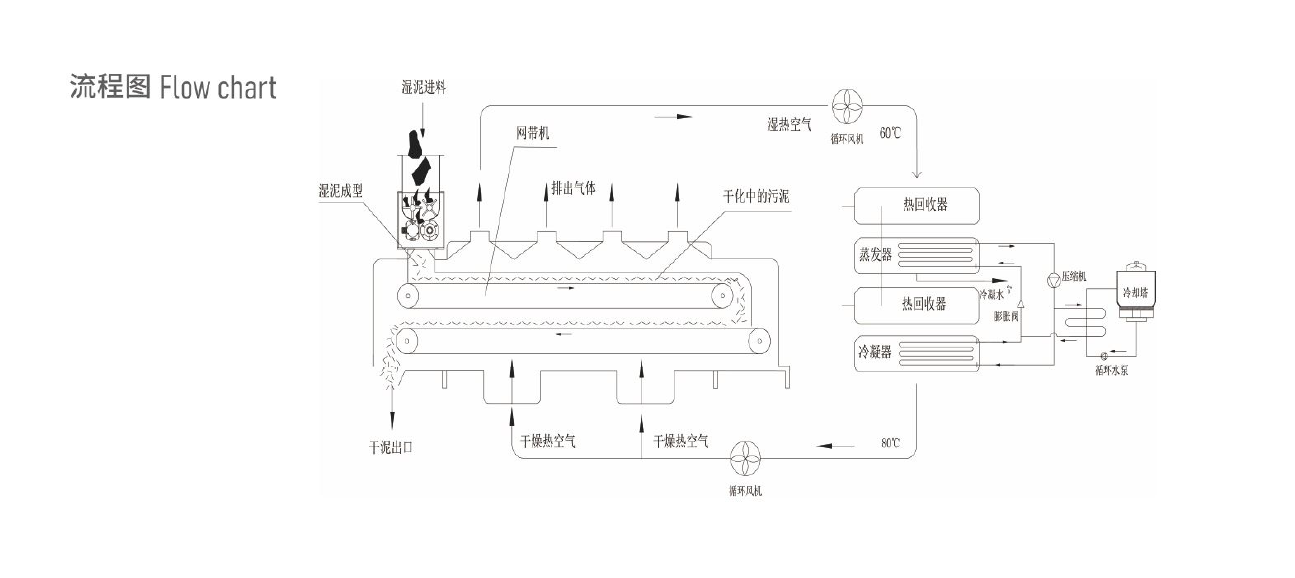

Heat pump heat recovery system, 100% total heat utilization

Moisture content below 10%, reduction over 80%

online service

Tel:+86-577-86610392

Email: jinggong@188.com

|

Model |

JCD1200SL/FL |

JCD2400FL |

JCD4800FL |

JCD7200FL |

JCD9600FL |

JCD10800SL |

JCD16200SL |

JCD21600SL |

JCD27000SL |

JCD32400SL |

JCD37800SL |

JCD43150SL |

JCD48600SL |

JCD54000SL |

|

Standard water removal / 24h |

1200kg |

2400 kg |

4800 kg |

7200 kg |

9600 kg |

10800kg |

16200 kg |

21600 kg |

27000 kg |

32400 kg |

37800 kg |

43200 kg |

48600 kg |

54000 kg |

|

Water removal / h |

50 kg |

100 kg |

200 kg |

300 kg |

400 kg |

450kg |

675kg |

900kg |

1125kg |

1350kg |

1575kg |

1800kg |

2025kg |

2250kg |

|

Operating power |

15kw |

27 kw |

51 kw |

75 kw |

106 kw |

105kw |

155kw |

205kw |

255kw |

305kw |

355kw |

405kw |

455kw |

505kw |

|

Heat pump host

Number of modules

|

1 set |

1 set |

2 set |

3 set |

2 set |

2 set |

3 set |

4 set |

5 set |

6 set |

7 set |

8 set |

9 set |

10 set |

|

Cooling method |

Water-cooled / air-cooled |

Air-cooled |

Air-cooled |

Air-cooled |

Air-cooled |

Water-cooled SL |

||||||||

|

Cooling water flow

Δt = 15 ℃

|

0.5m3/h See note 1 |

/ |

/ |

/ |

/ |

8.5m3/h |

12.8m3/h |

17m3/h |

21m3/h |

25.5m3/h |

30m3/h |

34m3/h |

38m3/h |

42.5m3/h |

|

The refrigerant |

R134a |

|||||||||||||

|

Power supply |

(220V\380V\440V)/3H/50Hz(60Hz) |

|||||||||||||

|

Drying temperature |

50 ~ 60 ℃ (return air) / 65 ~ 80 ℃ (supply air) |

|||||||||||||

|

Control System |

Touch screen + PLC programmable controller |

|||||||||||||

|

Application scope of wet mud |

Water content (75% -81%) (other water content is customized) |

|||||||||||||

|

Dry water |

Frequency conversion adjustment, moisture content (10% -50%) |

|||||||||||||

|

Forming method |

Cut |

|||||||||||||

|

Dimensions (L * B * H) mm |

3400 *1510 *2180 |

3910 *2350 *2480 |

6610 *2350 *2480 |

9310 *2350 *2480 |

8020 *3150 *3250 |

8020 *3150 *3250 |

11270 *3150 *3250 |

14520 *3150 *3250 |

17770 *3110 *3200 |

20920 *3150 *3250 |

24570 *3150 *3250 |

27520 *3150 *3250 |

30770 *3150 *3250 |

34020 *3150 *3250 |

|

Structure type |

Outfit |

Outfit |

Assembly |

Assembly |

Assembly |

Assembly |

Assembly |

Assembly |

Assembly |

Assembly |

Assembly |

Assembly |

Assembly |

Assembly |

|

Weight |

2Ton |

3.2Ton |

5.7Ton |

7.8Ton |

9Ton |

9Ton |

12.3Ton |

15.5Ton |

17.7Ton |

21.9Ton |

25.1Ton |

28.3Ton |

31.5Ton |

34.7Ton |

Note 1: JCD1200FL (air-cooled) model does not require cooling water. 2: Product updates will cause changes in parameters, please contact technology for details. 3: For details of customized models, please communicate with technology.

Features

Heat pump heat recovery system, 100% total heat utilization

Moisture content below 10%, reduction over 80%

Ultra-low operating cost per ton of 180-degree electricity

50 degrees low temperature operation, safer

0 emissions, no odorous emissions, condensate can be discharged straight, more hygienic without dust

Online enquiry

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

Related products

Low temperature sludge dewatering machine

Heat pump heat recovery system, 100% total heat utilization

Moisture content below 10%, reduction over 80%

Automatic on-site self-cleaning filter

High degree of automation, processing capacity;

Self-cleaning anti-pollution, and uninterrupted water supply;

Bottle Cleaner & Blower

The machine uses advanced air knife technology, stable performance, low temperature operation, high visibility, good drying effect, suitable for high speed production line.

Learn MoreHigh pressure backwash filter

1. Effectively solve the problem of manual replacement and cleaning of the filter drum of bottle washing machine. Before using the high-pressure filter, the packaging workshop personnel have to frequently clean the filter drum, but after using the high-pressure filter, the filter drum is no longer cleaned.

2. not only effectively protect the bottle washing machine spray pipe is not blocked. Before the use of high-pressure filters, the packaging workshop personnel three to five days to fully clean the spray pipe once. After using the high pressure filter, there is no need to manually clean the spray pipe for at least one month.