High pressure backwash filter

1. Effectively solve the problem of manual replacement and cleaning of the filter drum of bottle washing machine. Before using the high-pressure filter, the packaging workshop personnel have to frequently clean the filter drum, but after using the high-pressure filter, the filter drum is no longer cleaned.

2. not only effectively protect the bottle washing machine spray pipe is not blocked. Before the use of high-pressure filters, the packaging workshop personnel three to five days to fully clean the spray pipe once. After using the high pressure filter, there is no need to manually clean the spray pipe for at least one month.

I. Product Advantages

1. Effectively solve the problem of manual replacement and cleaning of the filter drum of bottle washing machine. Before using the high-pressure filter, the packaging workshop personnel have to frequently clean the filter drum, but after using the high-pressure filter, the filter drum is no longer cleaned.

2. not only effectively protect the bottle washing machine spray pipe is not blocked. Before the use of high-pressure filters, the packaging workshop personnel three to five days to fully clean the spray pipe once. After using the high pressure filter, there is no need to manually clean the spray pipe for at least one month.

3. Reducing impurities in the lye, increasing the brightness of the lye, guaranteeing the washing rate of bottle washing, improving the lye replacement cycle, and reducing market complaints. Before using the high pressure filter, the packing workshop staff had to replace the new lye once in five to six days during the peak season. After using the high pressure filter, the lye replacement cycle has been extended to eight to nine days.

4. After using the high-pressure filter, the packaging workshop saves a lot of labor input costs while improving work efficiency (it is expected to save more than RMB 200,000 yuan a year in saving lye, steam, water and labor).

II. Product features

1. the filtration precision can be selected from 500 to 3000 microns, with large filtration area and high dirt-holding capacity, which can be customized by users according to the actual working conditions.

2. The cleaning mode is simple, and the cleaning cycle is controlled by PLC, which can realize automatic cleaning and sewage disposal. The parameters in the control system of automatic self-cleaning filter can be adjusted.

3. There is motor overload protection, which can effectively protect the motor.

4. The equipment has no stopping filtration, the whole backwashing process does not stop, and filtration and backwashing are carried out at the same time.

5. backwashing is completed automatically, eliminating the need for manual removal of filter elements and other operations.

6. the connection with the user pipeline is flange connection, the flange adopts the national standard flange, strong generality.

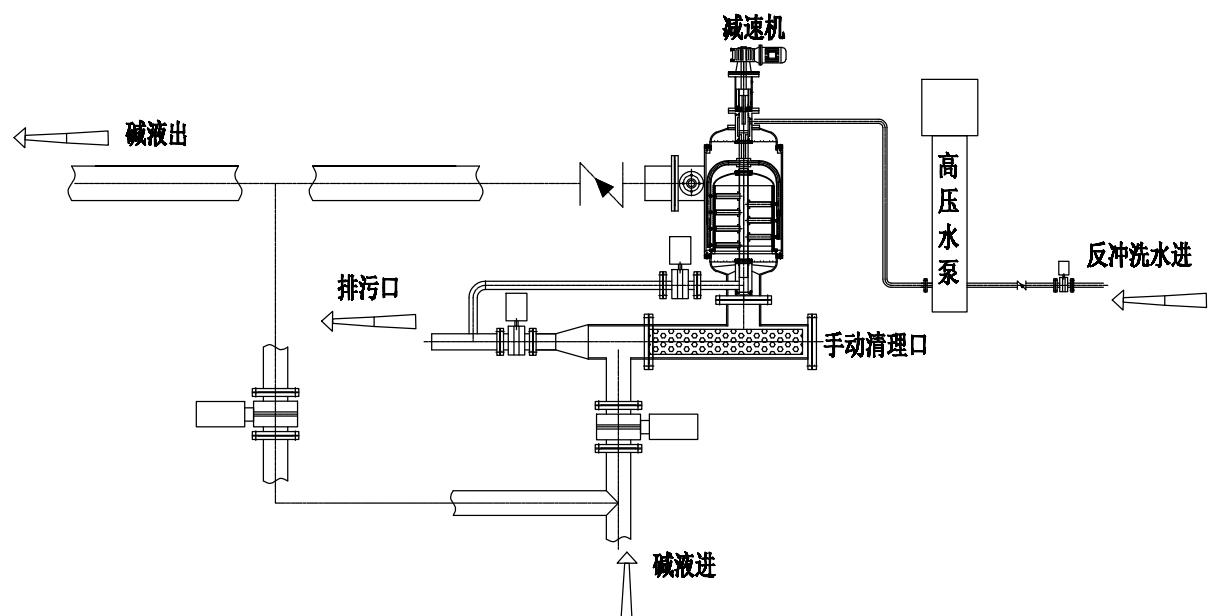

III. Flow chart (see below)

Online enquiry

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

Related products

High pressure backwash filter

1. Effectively solve the problem of manual replacement and cleaning of the filter drum of bottle washing machine. Before using the high-pressure filter, the packaging workshop personnel have to frequently clean the filter drum, but after using the high-pressure filter, the filter drum is no longer cleaned.

2. not only effectively protect the bottle washing machine spray pipe is not blocked. Before the use of high-pressure filters, the packaging workshop personnel three to five days to fully clean the spray pipe once. After using the high pressure filter, there is no need to manually clean the spray pipe for at least one month.

Bottle Cleaner & Blower

The machine uses advanced air knife technology, stable performance, low temperature operation, high visibility, good drying effect, suitable for high speed production line.

Learn MoreWasted label compressor

The machine is professional compressed surface water with the material,through the spiral, hydraulic and other means to compress the water with thematerial,

Learn MoreAutomatic on-site self-cleaning filter

High degree of automation, processing capacity;

Self-cleaning anti-pollution, and uninterrupted water supply;