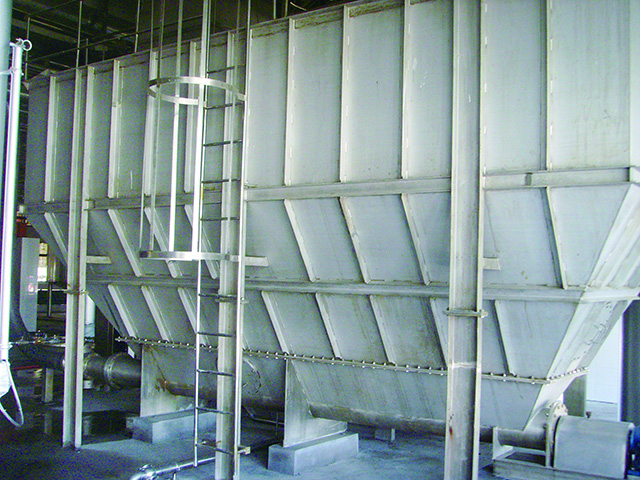

Lauter System

Use the speed control system of frequency conversion control, two motors of plow tank, draintank divided driving, lifting system of electric hydraulic.

Wort filtering system:

★ Use the speed control system of frequency conversion control, two motors of plow tank, draintank divided driving, lifting system of electric hydraulic. The single transmission arm drive out thetank door dynamoelectriclly, with the large diameter recessed plate, single transmission armdrive out the tank door dynamoelectric, also there has floating construction between the singletransmission arm and dynamoelectric drive out the tank door, in the upward movement to shutdown will automatically adjust for balance according to the stress situation, wide sealing surface,anti leakage, stable and reliable of operation.

★ The structure of plow tank is more reasonable: flexible regulation of rotate speed, in the rangeof 0.04~0.4rpm for regulation. Various forms of stainless steel plow knife farming transplaceddistribution, complex disposition to meet the needs of plow tank of horizontal and vertical. Theapplication of original wort plow tank technology, shorten the filter time of the original wort.

★ The structure of dump tank is reasonable: divide the dump tank scraper to six different sizes andangles, when rotating push the tank to the tank door smoothly. The rotate speed of plow knife armregulate in the range of 0.4 ~ 4.5rpm, effectively shorten the plowing tank time for≤ 12min. Theplow tank device hooking and unhooking automatically, easy to operation.

★ Reasonable configuration of the plow knife arm: According to the different diameters of filtrationtanks to configurate different numbers of plow knife arms, to achieve the best optimized ofconfiguration. The lift travel of plow knife hydraulic pressure regulate between 0~400mm, liftingspeed of 400mm/min, divide to six different gears.

★ Use the anti oxidation way to wash the tank: First, the special ball washing, second is try to bemore close to the liquid level, make the wash-water spraying in the liquid level of close distanceand form the surface flowing down.

★ Reflow use the central reflow technology: the two reflow mouths from the center tower bottomevenly distribute under the whole filter liquid level, small effect to the tank layer, and resistant tooxidation.

★ The filter liquid level control use the balance column (tank) structure to precise feedback thetightness of tank layer, in order to frequency conversion and control the filter speed, adjust thespeed and depth of plow tank, shorten the time of filter and ensure the clearance and brightnessofwort.

★ 4~5mm thick channeling type filter sieve plate, high intensity, very smooth and will not easy ofdeformation, improve the filter quality and speed of plow tank speed. Reasonable layout of thecollecting mouth of the large diameter wort, greatly reduce the effect of speed of filter wort to thetank layer, ensure the smooth control of wort filtration process.

★ Cleaning of the sieve plate: the fan washing nozzle of pulse type 180 ° which is special designed,uniform distribution, the same direction of water flow , raise the cleaning effect.

★ Feeding mandrill valve of filter tank bottom air-operated whose performance is fine, safe andreliable of automatic control.

Online enquiry

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

Related products

Lauter System

Use the speed control system of frequency conversion control, two motors of plow tank, draintank divided driving, lifting system of electric hydraulic.

Learn MoreMashing & Rice Cooking System

Suspended mixing electric machine, SEW deceleration system. Compact ofstructure, low maintenance, low power and stable operation.

Learn MoreMashingCIP System

Concentrated acid concentrated alkali adding device, alkali tank, acid tank, recycling water tank.

Learn MoreHeat Energy Recollection System

With the heat interchanger to replace and recover the heat water of second steam which comeout through the normal pressure or low pressure boiling process

Learn More