Vacuum drum device

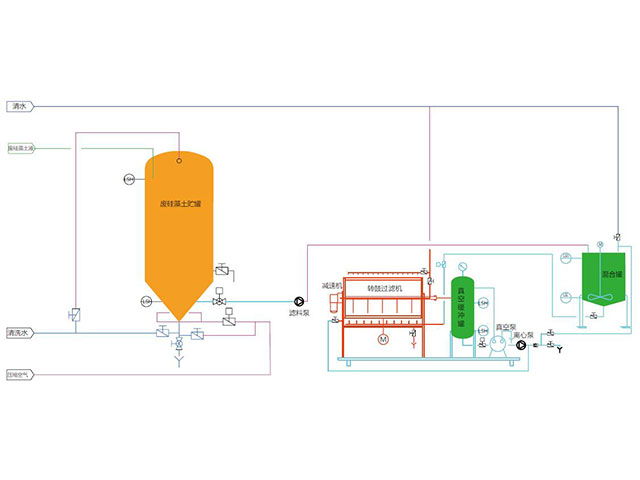

Vacuum drum filter equipment is mainly used for liquid waste treatment diatomaceous earth, hence called diatomaceous earth waste treatment device.

Working:

Vacuum drum filter equipment is mainly used for liquid waste treatment diatomaceous earth, hence called diatomaceous earth waste treatment device. The device is driven by the reducer filter continuous uniform rotation of the drum by a vacuum pump pressure difference formed by the filter drum within the dispenser, the flow through the filter material was filtered off with suction, the water in the feed solution was continuously sucked into the discharge or recycle tank; and solid materials (such as diatomaceous earth) is uniformly adsorbed on the outer surface of the drum forming a cake layer, when the layer reaches a certain thickness of the filter cake, through the discharge zone blade automatic feed, and the feed to the cutting blade position of the layer cake, the solid material was cut to take a continuous chute in the bag handle. This cycle, continuous suction filtration operation, the water discharge of waste residue and require separate treatment, to environmental protection, health requirements.

Configuration or composition:

★ Diatomite waste tank;

★ Mixing tank (with agitation);

★ Drum filter, unloading bodies and chassis;

★ Buffer tank;

★ Pump: filtrate pumps, centrifugal pumps, vacuum pumps;

★ Valves, pipe fittings;

★ Control system.

Technical parameters:

★ Main material: SS304;

★ Filter area: 2.5~6m2;

★ Drum diameter:¢600~1000mm

★ Working pressure: -0.2 ~ -0.6bar;

★ Processing capacity: 100 ~ 300kg / h, (about 60% moisture content), or a mixture of 1.5 ~ 2.5m3 / h;

★ Total installed capacity: 10 ~ 13kw;

★ Area: 10 ~ 15 m2;

★ Dimensions: 2700×1500×1600mm - 3800×2600×2700mm

Main features:

★ Integrated filter drum is easy for evenly pre-coating and washing

★ Backwashing function guarantees the cleaning for inside to outside

★ Labor intensity is low due to continuous autornatic operation

★ Different moisture filter cake can be formed through controlling the speed by frequency converter

★ Compact construction covers a small area,that is more simplified,stable and reliable

Control system:

The system uses PLC programming automatic control, touch screen panel settings can be realized precoat filtration process automatic control, can automatically be adjusted according to the blade feed material liquid filtration efficiency filtration with automatic protection function scraper stroke, liquid-liquid filter material bit automatic control, automatic suction filtered material control functions. Control device includes a vacuum drum filter, waste diatomite tank, solid-liquid pumps, waste soil and waste soil stirred tank tank top and bottom level control.

Online enquiry

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

Related products

Low temperature sludge dewatering machine

Heat pump heat recovery system, 100% total heat utilization

Moisture content below 10%, reduction over 80%

Wasted label compressor

The machine is professional compressed surface water with the material,through the spiral, hydraulic and other means to compress the water with thematerial,

Learn MoreHigh pressure backwash filter

1. Effectively solve the problem of manual replacement and cleaning of the filter drum of bottle washing machine. Before using the high-pressure filter, the packaging workshop personnel have to frequently clean the filter drum, but after using the high-pressure filter, the filter drum is no longer cleaned.

2. not only effectively protect the bottle washing machine spray pipe is not blocked. Before the use of high-pressure filters, the packaging workshop personnel three to five days to fully clean the spray pipe once. After using the high pressure filter, there is no need to manually clean the spray pipe for at least one month.

Automatic on-site self-cleaning filter

High degree of automation, processing capacity;

Self-cleaning anti-pollution, and uninterrupted water supply;

-112649.jpg)